| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : DLX

Model Number : 1Cr13Al4

Place of Origin : China Jiangsu

MOQ : 5

Price : Negotiable

Payment Terms : L/C, T/T, Western Union, MoneyGram

Supply Ability : 500 tons per month

Delivery Time : 7-20 days

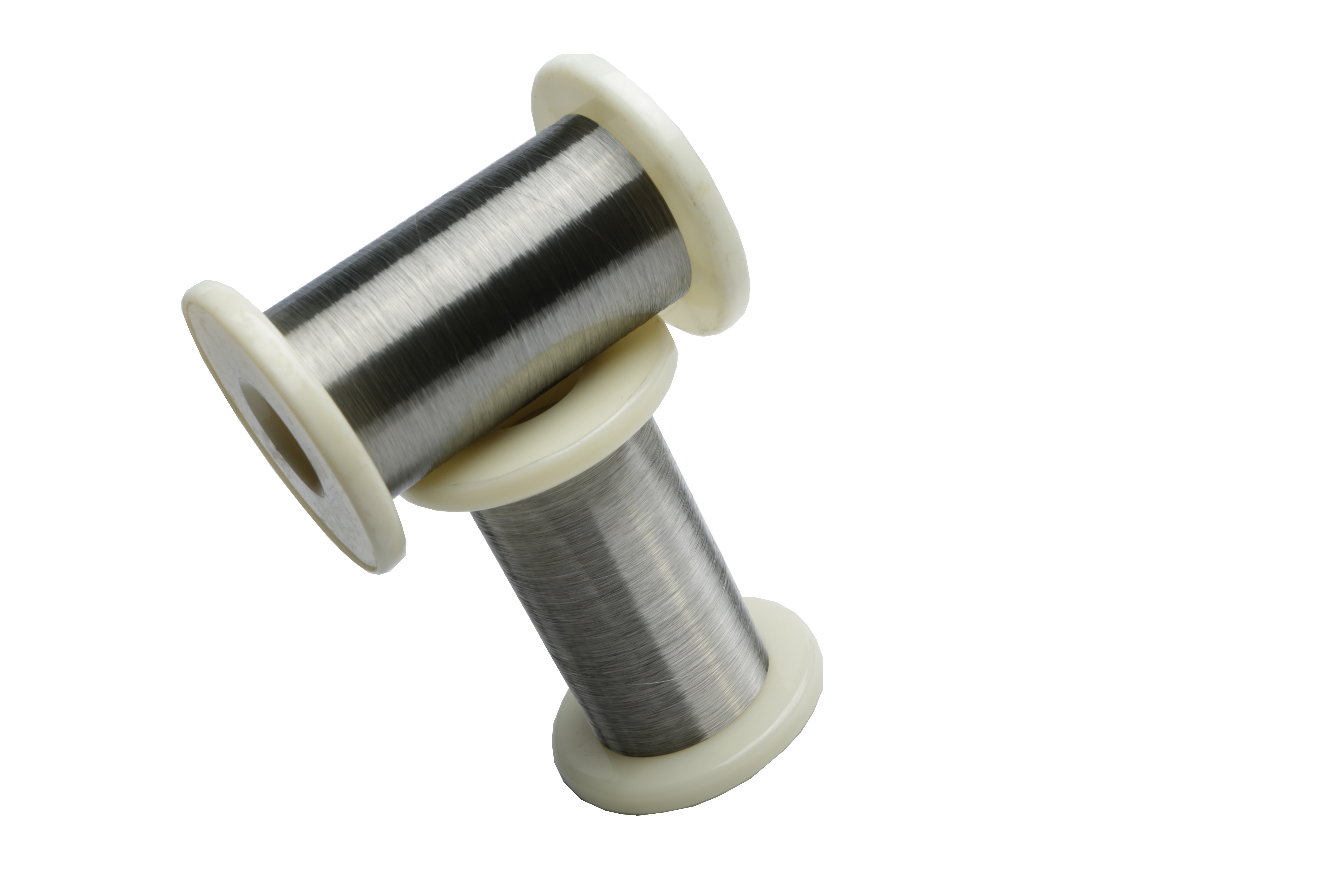

Packaging Details : Spool package with Carton box, Coil package with polybag

Material : Ferrous Chromium Aluminum

Resistivity : 1.25+/-0.05

Tensile Strength : 580-680MPA

Elongtation : ≥12%

Application : Heating, Resistivity

Condition : Hard / Soft

Sureface : Bright, Oxided, Acide

Maximum Temperature : 950℃

Melting Point : 1450℃

Certification : CE,ROHS

1Cr13Al4 alloy is a high resistance electric heating alloy, known for its excellent corrosion resistance and high-temperature strength. It has a high electrical resistivity and a low resistance temperature coefficient. The main components of 1Cr13Al4 include chromium, aluminum, nickel, etc., which endow the alloy with good electrical resistivity, high-temperature oxidation resistance, and corrosion resistance.

The 1Cr13Al4 resistance wire plays an important role in resistance performance testing. When conducting resistance performance tests, 1Cr13Al4 resistance wire is often used as one of the test samples to evaluate its resistance characteristics and stability. This type of testing typically involves measuring the resistance value of the wire and testing it under different temperatures, humidities, or other environmental conditions to determine its performance under various operating conditions.

The resistance characteristics of 1Cr13Al4 resistance wire are determined based on its material composition and manufacturing process. Therefore, in resistance performance testing, it is compared to standard specifications to ensure that it meets the expected resistance values and performance requirements. Various measuring devices and instruments such as multimeters, bridges, etc., may be used during the testing process to ensure accurate measurement of the resistance wire.

Additionally, durability testing may also be conducted in resistance performance testing to assess the stability and durability of 1Cr13Al4 resistance wire under long-term use and different operating conditions. This type of testing can help determine the reliability and lifespan of the resistance wire and provide reference for its performance in practical applications.

Overall, the application of 1Cr13Al4 resistance wire in resistance performance testing aims to evaluate its resistance characteristics and stability under different conditions to ensure that it meets the expected performance requirements and supports its reliability in various industrial applications.

| Alloy Nomenclature Performance | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| Main Chemical composition | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| Re | opportune | opportune | opportune | opportune | opportune | opportune | opportune | |

| Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

| Nb0.5 | Mo1.8-2.2 | |||||||

| Max. continuous service temp. of element(°C) | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| Resistivity at 20ºC(μΩ·m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

| Density(g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

| Thermal conductivity(KJ/m·h·ºC) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | ||

| Coefficient of lines expansion(α×10-6/ºC) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

| Melting point approx.( ºC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| Tensile strength(N/mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

| Elongation at rupture(%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| Variation of area(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| Repeat Bending frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| Hardness(H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| Continuous Servicetime(Hours/ ºC) | -- | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥50/1350 | ≥50/1350 | |

| Micrographic structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

| Magnetic properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

| ||

| ||

| ||

| ||

| ||

|

|

Fecral Heating Alloy 1.6mm SWG16 1Cr13Al4 Heating Resistance Wire For Resistance Testing Images |